The Challenge

No two jobsites are the same – neither are mechanical systems. Every project has a unique set of challenges that our custom designed solutions are equipped to meet. Our units are constructed off-site and delivered as modular skids reducing time, improving safety, maximizing usable space, and ensuring quality installation.

Exploration

All systems are fully tailored to accommodate your specific requirements. During the exploratory phase, we partner with the design team to study project specifications, performance requirements, ongoing maintenance considerations, and site challenges to design a customized solution for you.

Design and Detail

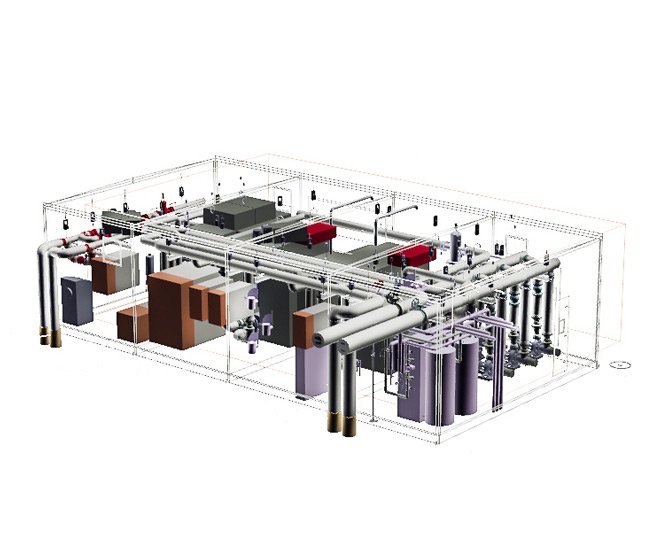

We have a robust team of experienced BIM coordinators that design personalized solutions. When working in collaboration with our project managers and tradespeople, design, constructability and service considerations are factored into our dynamic 3D Revit model. Our use of Navis works provides owners and operators with a virtual representation of their space prior to fabrication, allowing for concerns to be addressed ahead of time.

Off-Site Construction

MMS has a team of highly experienced pipefitters, plumbers and designers that handcraft your customized solution in our environmentally controlled fabrication shop. Our 70,000 SF ISO 9001:2015 certified facility ensures the highest level of quality craftsmanship to meet and exceed your expectations.

Start Up and Beyond

We inspect all equipment at our Fab Shop before shipping to minimize start up and commissioning time. Our service team is available to support with the installation, start up and commissioning. A representative is always available for your ongoing service needs and preventative maintenance check-ups.